Measurement technology

The robust housing is the core of VISPIRON ROTEC, which connects the sensors to the evaluation software on a measuring computer via integrated measuring cards in the RASdelta. We offer you comprehensive and application-oriented measurement data acquisition of torsional vibrations, temperature, acceleration, speed and sound. Depending on your requirements, you can exchange the powerful boards and adapt your measuring device.

Sensors

-

Click to view Differential sensorDifferential sensor

-

Click to view Laser sensorLaser sensor

-

Click to view Valve lift sensorValve lift sensor

The magneto-resistive (MR) differential sensors from ROTEC are used to detect rotational speeds on ferromagnetic gears and are available in various designs.

- Two-part design - the preferred direction can be set after mounting the sensor

- Suitable for the standard temperature range

- Insensitive to external influences such as oil and dirt

- Optionally with direction detection

TYPE B

TYPE B- Short sensor length

- Standard temperature sensor with detachable connection cable

- High temperature sensor with molded cable connection

- Insensitive to external influences such as oil and dirt

- Angled sensor head

- Standard temperature sensor with detachable connection cable

- High temperature sensor with molded cable connection

- Insensitive to external influences such as oil and dirt

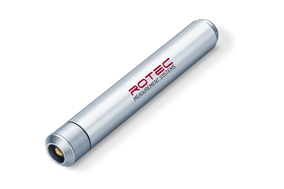

The optical laser sensor is used to detect rotational speeds using the reflex method. Depending on the application, a ROTEC zebra disk or zebra band is scanned. The target can be scanned from the front or via a deflecting mirror at a 90° angle.

- Scanning of the object from the front or via a deflecting mirror at a 90° angle possible

- Fiber optic cables available with textile or metal sheathing

- Opt. with ROTEC zebra disk / zebra band

The magneto-resistive (GMR) sensor for valve lift measurement from Sensitec is designed for use on ferromagnetic tooth structures. A strong magnet provides the necessary magnetic field. The sensor elements are encapsulated in a very small housing. The compact integration supports optimum coordination between sensor and magnet, which enables a very high signal quality.

- Very small size

- Magnetically biased

- Wired ready for connection

Electronics

-

Click to view Differential Sensor AdapterDifferential Sensor Adapter

-

Click to view Rotary Encoder AdapterRotary Encoder Adapter

-

Click to view 4-fold Sensor4-fold Sensor

-

Click to view Laser Tachometer 3Laser Tachometer 3

-

Click to view Encoder Phase ShifterEncoder Phase Shifter

-

Click to view Valve lift measurement moduleValve lift measurement module

The differential sensor adapter (DSA) converts the sinusoidal signal of the ROTEC magnetic sensor into a pulse sequence of needle pulses with TTL level, which is processed by the RASdelta speed measurement card. The analog sensor signal and the digital pulse sequence can be tapped separately at the scope output of the electronics. The trigger point (triggering of the digital pulse) can be set individually. The electronics can optionally trigger the rising, falling or both edges of the incoming sensor signal.

- Converts sinusoidal signals into a pulse train of needle pulses with TTL level

- Provides analog sensor signal and digital pulse sequence at separate "Scope" socket

- Selectable trigger edges (rising/falling/both)

- Supplies sensor with voltage

- Power supply via speed measurement card

The Inline TTL Digitizer (Inline-DSA) is the compact version of the ROTEC Differential Sensor Adapter (DSA) and is particularly suitable for mobile use. The electronics convert the sinusoidal signal from the ROTEC magnetic sensor into a TTL pulse sequence, which is processed by the RASdelta speed measurement card.

- Converts sinusoidal signals into pulse trains with TTL level

- Supplies magnetic sensor with voltage

- Power supply via speed measurement card

The rotary encoder adapter is used to adapt rotary encoder signals and incremental linear scales with TTL or SIN/COS signals. The electronics use the signals from the incremental encoder to generate a digital pulse sequence with TTL level, which serves as the measuring signal. The rotary encoder adapter records the encoder signals forwards and backwards and derives direction information from them. The signals for the speed and direction of rotation as well as the reference pulse (if available) are recorded and processed by the RASdelta speed measurement card. The reference pulse can also be tapped at a separate socket and used as a start trigger for the measurements.

- Adapts rotary encoder signals / incremental linear scales with TTL or SIN/COS level

- Generates digital pulse sequence with TTL level

- Derives direction information from the encoder signals

- Detects speed, direction of rotation and reference pulse

- Provides reference pulse as start trigger

- Supplies incremental encoder with voltage

- Power supply via speed measurement card

- Processes differential or single-ended signals

- Enables the speed pulses to be reduced

The Inline DGADP TTL (Inline Incremental Encoder Adapter) is the compact version of the ROTEC Rotary Encoder Adapter and is particularly suitable for mobile use. The adapter is also available in two versions: for TTL and for HTL incremental encoders.

The electronics generate a digital pulse sequence with TTL level from the signals of the incremental encoder, which serves as the measuring signal. The Inline DGADP records the encoder signals forwards and backwards and derives direction information from them.

- Generates digital pulse sequence with TTL level

- Derives direction information from the encoder signals

- Supplies incremental encoder with voltage

- Power supply via speed measurement card

- Reverse polarity protected

The 4-fold sensor electronics are used to measure speeds with direction detection. The electronics convert the analog sinusoidal signal generated by the sensor into a digital pulse sequence with TTL level, which serves as the measuring signal. Together with the analog cosine signal, the direction information is also derived. The analog sensor signal and the digital TTL pulse sequence can be tapped separately via a scope output.

- Measures speeds with direction detection

- Converts analog sinusoidal signal into digital pulse train with TTL level

- Derives directional information from the measurement signal

- Supplies sensor with voltage

- Power supply via speed measurement card

The ROTEC laser tachometer is used for optical measurement of the rotational frequency or speed. The electronics generate a power-controlled laser light which is transmitted from the sensor to a black and white pattern attached to the measurement object. The light/dark transitions of the measurement object are scanned using the reflex method. The optical signal received is first converted into an analog signal and then into a digital signal. This results in a pulse sequence with TTL level and speed-proportional frequency. The analog sensor signal and the digital pulse sequence can be tapped separately at the scope output of the electronics.

- Measures rotation frequency / speed optically

- Generates power-controlled laser light

- Scans light-dark transitions of the measurement object using the reflex method

- Converts optical signal to digital signal with pulse train (TTL level)

- Provides the raw signal and the speed pulse sequence at a separate "Scope" socket

- Power supply via speed measurement card

Der ROTEC Laser Tachometer 3 dient zur optischen Messung der Drehfrequenz bzw. Drehzahl. Die Elektronik erzeugt ein leistungsgeregeltes Laserlicht, das vom Sensor auf ein am Messobjekt angebrachtes schwarz/weiß-Muster übertragen wird. Die Hell-Dunkel-Übergänge des Messobjekts werden im Reflexverfahren abgetastet. Das empfangene optische Signal wird erst in ein Analogsignal und dann in ein digitales Signal umgewandelt. Daraus resultiert eine Impulsfolge mit TTL-Pegel und geschwindigkeitsproportionaler Frequenz. Am Scope-Ausgang der Elektronik können das analoge Sensorsignal sowie die digitale Impulsfolge separat abgegriffen werden.

- Verzögert das originale Referenzsignal um eine einstallbare Anzahl an Drehzahlpulsen

- Stellt synthetischen Referenzimpuls an separater Buchse zur Verfügung

- Versorgt Rotary Encoder Adapter und Sensor mit Spannung

- Spannungsversorgung durch Drehzahlmesskarte

The electronic valve train measuring module (ELVTMM) serves as an evaluation unit for measurements on the valve train. The electronics condition the sensor signal and calculate the valve stroke with an accuracy of +/- 10 μm. The result is provided at the BNC connector as an output voltage between 0-10 V, proportional to the valve movement. The valve train measuring module offers up to four measuring channels, a high resolution and has a high sampling frequency of the raw sensor signals. The valve position is recorded within 1 μm and output in real time as an analog voltage. This means that even very fast movements can be reliably recorded.

The GMR sensor adapter is suitable for valve lift measurements with the FixPitch sensor from Sensitec (GLM711AVB). The electronics are used to amplify the recorded raw signals and ensure a noise-free signal and sufficient bandwidth (signal bandwidth > 100 MHz / amplitude response 0.1 dB, up to 300 MHz). The amplified sensor signals are output via separate sine and cosine outputs. It is possible to connect two sensors in parallel.

RASdelta measurement boards

-

Click to view Trigger boardTrigger board

-

Click to view Speed boardSpeed board

-

Click to view Analog boardAnalog board

-

Click to view Temperature boardTemperature board

-

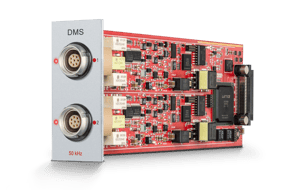

Click to view DMS boardDMS board

-

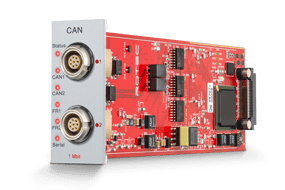

Click to view CAN-BUS boardCAN-BUS board

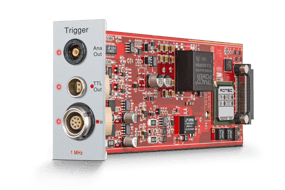

- Synchronizes all measuring cards, channels and cascaded systems

- 1x TTL trigger input with adjustable threshold values

- 2x TTL output + 1x analog output

Power supply for electronic units (DC 5 V and 12 V; 5 W) - Data transmission via Ethernet

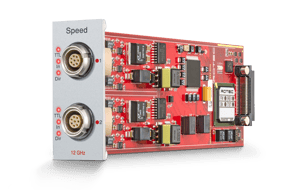

The RASdelta Speed Board records precise multi-channel and digital speed measurement data for all transmission, control and auxiliary drive tests. It is therefore the basis for torsional vibration analysis. The data is recorded via magnetic, angle-equidistant scanning, an incremental encoder or a laser.

- 2-channel measuring card with 12 GHz counter clock (time resolution = 0.081 nanoseconds)

- Signal inputs for direction and reference pulse detection

- Adjustable values for trigger threshold and edge

- Operating modes: speed, frequency, duty cycle, on/off ratio

The RASdelta Analog Board measures analog variables such as airborne and structure-borne sound, acceleration, temperature, displacement or pressure. These variables can be used to determine the position of a sound source or to analyze the valve train or cylinder pressure. The analog measurement data is acquired by equidistant sampling.

- 2 analog voltage inputs, galvanically isolated

- AC and DC coupling, power supply for IEPE (ICP) sensors

- Adjustable voltage ranges for input signals

- 16 bit SigmaDelta ADC

- 3.2 MHz max. sampling rate for single-channel use

- 1.6 MHz max. sampling rate per channel for dual-channel operation

- 1.2 MHz analog bandwidth

- 3 analog voltage inputs, galvanically isolated

- AC and DC coupling, power supply for IEPE (ICP) sensors

- Adjustable voltage ranges for input signals

- 24 bit SigmaDelta ADC

- 50 kHz max. sampling rate per channel

- 24 kHz analog bandwidth

Das RASdelta DMS (strain gauge) Board ist ein integrierter Zweikanal-Gleichspannungsverstärker für die Signalerfassung von Dehnungsmessstreifen-basierten, piezoresistiven, magnetoresistiven oder potentiometrischen Aufnehmern. Dazu gehören Kraft-, Drehmoment-, Druck-, Weg- und Winkelsensoren oder Maßstäbe. Die Karte benötigt keine zusätzlichen Messverstärker.

Max. Abtastrate: 50 kHz pro Kanal

Unterstützt Vollbrücken- und Halbbrückenanwendungen

Einstellbare Brückenversorgungsspannung: 1 V, 2,5 V, 5 V, 10 V

Unterstützt Vierdraht- und Sechsdraht-Konfiguration

Automatischer Nullabgleich

Erkennung von Leitungsunterbrechungen/Burn-Out

- Zweidraht- und Vierdrahtkonfiguration für Pt 100/1000

The RASdelta strain gauge card is an integrated dual-channel DC voltage amplifier for signal acquisition from strain gauge-based, piezoresistive, magnetoresistive or potentiometric transducers. These include force, torque, pressure, displacement and angle sensors or scales. The card does not require any additional measuring amplifiers.

- 2-channel measurement board

- Max. Sampling rate: 50 kHz per channel

- Supports full bridge and half bridge applications

- Adjustable bridge supply voltage: 1 V, 2.5 V, 5 V, 10 V

- Supports four-wire and six-wire configuration

- Automatic zero adjustment

- Detection of line interruptions/burn-out

The CAN-BUS board records CAN and OBD-II variables and evaluates them in relation to the torsional vibration analysis. This means that existing variables can be included in the measurement without the need for additional sensor applications. In addition to OBD II, Raw CAN and SAE J1939 protocol, it is possible to record FD CAN data directly via the measurement PC and separate third-party hardware.

- 2-channel measurement board

- Max. Baud rate: 1 Mbit/s per channel

- Adjustable post-sampling rate

- CAN standard 2.0 A (11-bit identifier) and 2.0 B (29-bit identifier); OBDII; J1339; (CAN-FD via PC USB connection)

- Modes: active/passive listener

- Adjustable BUS termination (120 Ohm)

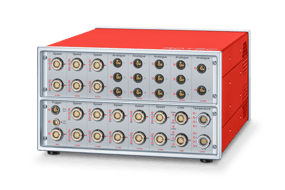

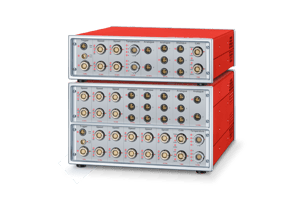

RASdelta Mainframe

The RASdelta mainframe connects sensors and measurement cards. The housing offers space for at least 8 measurement cards, which can be combined as required. The integrated fan also makes it insensitive to temperature. In this case, one of the front ends acts as the master and synchronizes the other devices in the cluster. With the data logger function, measurements can be configured and carried out directly on the touch display. The measurement data is saved on an SD card and can later be transferred to a PC for evaluation.

-

Click to view 8 slots8 slots

-

Click to view 16 slots16 slots

-

Click to view ClusterCluster

-

Click to view Data logger functionData logger function

- Space for 8 measuring cards

- Integrated touch panel display

- Insensitive to temperature, thanks to the integrated fan

- Measuring cards can be replaced if necessary

- Optionally with data logger function

- Space for 8 measuring cards

- Integrated touch panel display

- Insensitive to temperature, thanks to the integrated fan

- Measuring cards can be replaced if necessary

- Optionally with data logger function

- Slots can be expanded by cascading the RASdelta frontends

- One front end acts as master

- Integrated touch panel display

- Insensitive to temperature, thanks to the integrated fan

- Measuring cards can be replaced if required

- Opt. with data logger function

- Measurements are configured and carried out directly on the touch display

- Measurement data is saved on an SD card and can later be transferred to a PC for evaluation.